Precision CNC-Machined Outdoor Knives: Where Industrial Mastery Meets Wilderness Performance

As a leading OEM/ODM manufacturer in China’s blade production hub, we specialize in crafting high-performance outdoor knives through CNC machining and advanced metallurgy. With vertically integrated facilities spanning 3,000㎡ and 15+ years of expertise, we deliver precision tools trusted by global adventurers and tactical professionals.

1. CNC-Driven Precision Engineering

Our 5-axis CNC machining centers (±0.01mm accuracy)

transform premium steels (Böhler M390, S30V, ZDP-189) into blades with Rockwell hardness up to 67 HRC

. Key technical advantages include:

Ultra-Fine Edge Geometry: Optimized hollow/flat grinding (20° inclusive angles) ensures razor-sharp edges for bushcraft and survival tasks

.

Thermal Control: Vacuum heat treatment reduces hardness variance to ≤1 HRC, enhancing edge retention

.

Multi-Axis Efficiency: Simultaneous machining of blade profiles, jimping, and lanyard holes cuts production time by 30%

.

2. Material Innovation & Compliance

We engineer knives for extreme environments using:

Aerospace-Grade Alloys: Titanium-coated YXR7 steel (64-66 HRC) resists corrosion in saltwater

.

Smart Coatings: DLC (Diamond-Like Carbon) and TiAlN coatings reduce friction by 40% while preventing rust

.

Certified Safety: All products meet EN ISO 8442 (food safety) and ASTM F2992-14 (tactical knives) standards

.

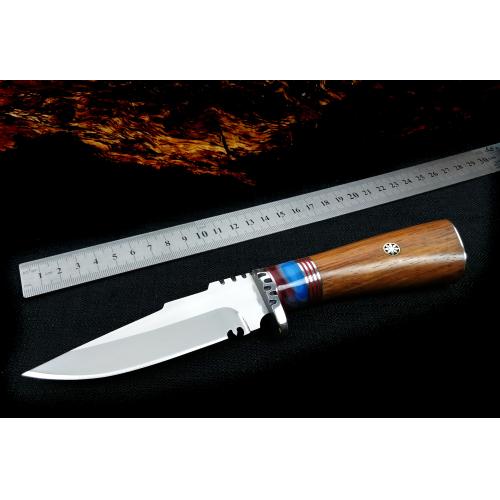

3. Customization for Global Brands

From EDC folders to full-tang survival knives, we support:

Logo Integration: Laser engraving (min. 8×8mm) and chemical etching for brand visibility

.

Functional Upgrades: MOLLE-compatible Kydex sheaths with drainage holes and QR code tracking

.

Bulk Flexibility: MOQ 50 units with 15-day lead times, 30% faster than traditional forging

.

4. Quality Assurance & Logistics

Our 3-stage inspection system

guarantees perfection:

XRF Testing: Verify steel composition (e.g., 3% carbon in ZDP-189)

.

Edge Integrity Check: 50,000 open/close cycles for folding knives

.

Salt Spray Testing: 96+ hours corrosion resistance validation

.

Global Reach: DDP shipping with pre-cleared HS codes (e.g., 8211.93.00)

, vacuum-sealed TPE packaging to prevent transit damage.

5. Why Partner With Us?

Cost Efficiency: CNC automation reduces labor costs by 25% vs. manual forging

.

Sustainability: Recyclable materials and energy-efficient machining align with EU Green Deal

.

Tech Support: Free CAD file optimization and 3D prototype rendering within 48 hours

.

Limited Offer: First 100 orders receive free Kydex sheath color upgrades (OD Green/Coyote Brown)